Why sterilize food?

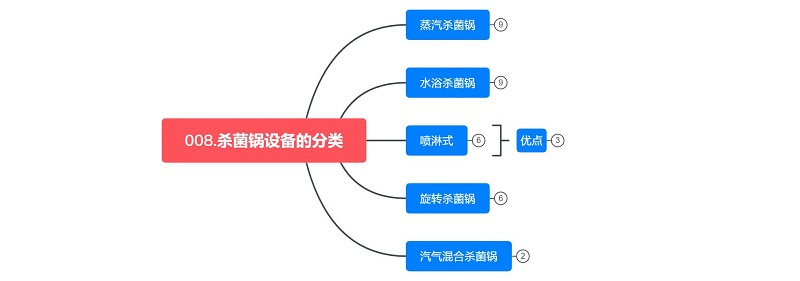

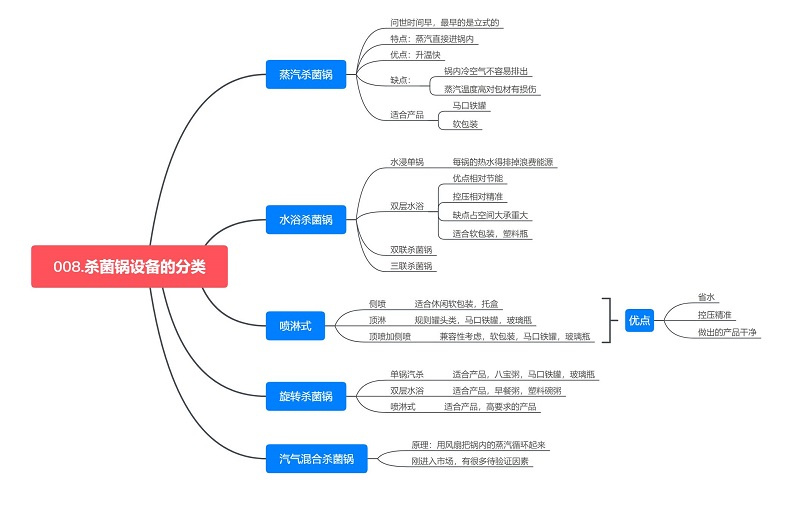

Classified by heat transfer medium:

01. Steam Retort Sterilizer.

Time period: Introduced early, originally vertical models..

Features: Steam directly enters the retort to heat the product.

Advantages: Fast heating.

Disadvantages: Difficult to remove cold air from the retort.

High steam temperature can damage packaging materials..

Suitable products: Tin cans, flexible packaging.

02. Water Retort Sterilizer. Water sterilization retorts are further divided into: 1. Spray-type sterilizer. 2. Immersion-type sterilizer.

Time period: Introduced later than steam retorts, initially single water retorts.

Features: Steam heats the water inside the retort, and the water then heats the product.

Advantages: Relatively energy-efficient.

Disadvantages: Large space required, large capacity..

Suitable products: Flexible packaging, plastic bottles.

Classified by movement:

01. Static Retort Sterilizer.

02. Rotating Retort Sterilizer.

Classified by control method:

01. Manual control.

02. Semi-automatic control.

03. Fully automatic control.

Classified by material:

01. Carbon steel: Q235.

02. Stainless steel 30408.

03. Stainless steel 316L.

Want to learn more? Click below: